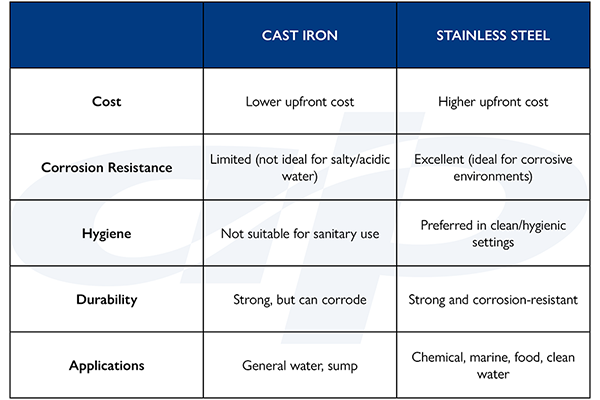

When selecting a pump, material choice is just as important as flow rate or power. Cast iron vs stainless steel pumps are among the most popular options, with each offering distinct advantages and limitations. In this article, we’ll break down the pros and cons of both and explore where cast iron and stainless steel pumps are best applied.

Cast iron pumps are significantly more affordable than those made from stainless steel or specialised alloys. For projects that require multiple pumps or operate on tight budgets, cast iron provides a practical solution without compromising on reliability. This cost efficiency makes it a go-to choice for many large-scale applications where multiple units are required.

Cast iron is known for its excellent tensile strength and structural integrity. It can withstand heavy loads, impacts, and pressure surges that may occur during pump operation. This robustness makes it suitable for tough working environments such as dewatering, drainage, or industrial water transfer where pumps may be subject to extreme operating conditions.

In applications where the pumped fluid may contain suspended solids—like stormwater, wastewater, or slurries—cast iron offers good resistance to abrasion. The material doesn’t wear down quickly from contact with sand, grit, or other particulates. This helps maintain performance over time and reduces the frequency of replacements or repairs.

The dense composition of cast iron naturally absorbs vibrations generated by the pump motor and impeller. This leads to smoother, quieter operation, which is beneficial in installations near residential areas or in buildings where noise is a concern. Reduced vibration also means less stress on seals, bearings, and other internal components, extending the pump’s overall lifespan.

Cast iron is one of the most common materials used in the pump industry, so spare parts and service expertise are widely accessible. In the event of wear or damage, many components can be easily refurbished or replaced. Its machinability means that repairs can often be done on-site or locally, minimizing downtime and maintenance costs.

Cast iron is susceptible to rust and oxidation when exposed to water and air over time—particularly in environments with high humidity, salinity, or acidity. Without protective coatings or liners, corrosion can eat away at the internal surfaces, causing leaks, reduced efficiency, and eventual failure. This makes cast iron pumps less suitable for coastal areas, chemical processing, or any application involving untreated water.

When it comes to handling corrosive or chemically reactive fluids, cast iron falls short. Substances like seawater, chlorinated water, or certain acids and alkalis can quickly degrade cast iron components. In these cases, materials like stainless steel, bronze, or engineered plastics are a better fit due to their superior chemical resistance.

Due to its porous surface and susceptibility to corrosion, cast iron is not approved for use in industries where hygiene is critical. Bacteria and contaminants can settle into microscopic pores and be difficult to remove, even with cleaning. Stainless steel, with its smooth, non-porous surface, is the preferred alternative in these settings.

Stainless steel is highly resistant to rust, oxidation, and chemical attack. This makes it ideal for use in corrosive environments such as coastal areas, chemical processing plants, and wastewater treatment facilities. Unlike cast iron, stainless steel maintains its integrity when exposed to moisture, salt, and a wide range of aggressive fluids—greatly extending pump life and reliability.

With a smooth, non-porous surface, stainless steel is easy to clean and resistant to bacterial growth. This makes it the preferred material in industries where hygiene is critical—such as food and beverage, pharmaceutical, and potable water systems. It complies with strict regulatory standards and ensures product purity throughout the pumping process.

Stainless steel offers excellent mechanical strength, allowing pumps to handle high pressures and temperatures without cracking, warping, or failing. It performs well under stress and in demanding environments where thermal cycling, vibration, or abrasive fluids are present. The material’s toughness also means it’s less prone to damage from impacts or handling errors, which is an advantage during transport and installation.

One of the key advantages of stainless steel is its adaptability. Whether you’re pumping drinking water, brine, acids, alkalis, or oil-based fluids, stainless steel can handle a wide range of substances without corroding or reacting. This flexibility means a single stainless steel pump model can often serve multiple purposes, reducing the need for different equipment across projects or industries.

Thanks to its corrosion and wear resistance, stainless steel pumps typically require less frequent maintenance than those made from cast iron or other materials. There’s less risk of scale buildup, rust flakes, or chemical damage, which can clog or degrade pump components. This translates to longer service intervals, fewer part replacements, and reduced downtime—resulting in lower total cost of ownership.

One of the most significant drawbacks of stainless steel pumps is their cost. Stainless steel is a more expensive raw material than cast iron or thermoplastics, and the manufacturing process can be more complex. For budget-conscious projects or non-critical applications, the higher initial investment may not always be justifiable.

Although stainless steel is resistant to many corrosive substances, it is not immune to all. Specific chemicals—such as strong chlorides, hydrochloric acid, or certain aggressive solvents—can cause pitting, crevice corrosion, or stress corrosion cracking over time. In these cases, higher-grade alloys or specialised materials like Hastelloy or duplex stainless steel may be required.

At Allied Pumps, we offer a comprehensive range of cast iron and stainless steel pumps to suit all applications—from general water transfer to aggressive chemical environments. We proudly supply trusted brands including Wilden, Blackmer, Flowserve, and more. Visit our industrial pumps page to view our full range.

For expert advice and tailored pump solutions, don’t hesitate to contact our team!

Contact us to learn about how we can help you with your pump needs.

CALL US NOW EMAIL US