Galvanised steel tanks are a vital part of infrastructure in mining and industrial operations. However, without proper protection, their longevity and performance can be significantly compromised. This is where tank liners play a critical role.

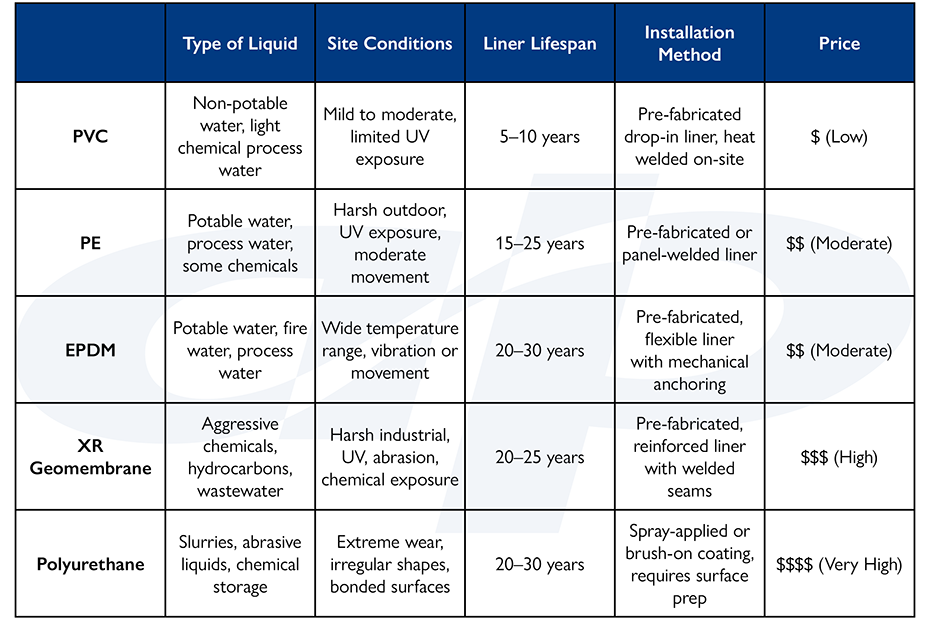

Today, we’ll explore why liners matter, the different options available, and how to choose the best one for your tank. We have also included a simple table that summarises the features and applications of each tank liner option.

Tank liners help significantly extend the lifespan of a steel tank by preventing direct contact between the water and the tank walls. This reduces wear and tear, minimises rust formation, and avoids the costly consequences of leaks or structural failures.

In regulated environments like mining, meeting water quality and workplace safety standards is non-negotiable. Liners can assist in achieving compliance with standards such as AS/NZS 4020 for potable water or environmental regulations concerning wastewater containment.

PVC is a flexible, cost-effective liner option commonly used in municipal scheme water storage. It offers satisfactory chemical resistance and is easy to install and weld on site. While PVC liners perform well in general applications, they have a shorter lifespan compared to other materials and may not be ideal for high-temperature or aggressive chemical environments.

Best suited for: Process water, potable water, and temporary or short- to medium-term use.

Polyethylene liners are known for their durability, chemical resistance, and compatibility with potable water. PE liners are inert and offer excellent resistance to UV degradation, making them ideal for long-term storage in demanding outdoor environments.

Best suited for: Potable water storage (certified to AS/NZS 4020), chemical containment, harsh climate or UV-exposed installations.

EPDM is a synthetic rubber liner known for its elasticity and long service life. It resists UV exposure, extreme temperatures, and a wide range of chemicals. EPDM is particularly suitable for tanks that may experience movement or flexing due to ground conditions or temperature shifts.

Best suited for: Fire water tanks, mining process water with variable conditions, sites with wide temperature fluctuations.

XR (also known as reinforced geomembranes) are high-performance liners designed for the most demanding applications. Made with a reinforced fabric base and coated with chemical-resistant polymers, XR liners offer exceptional puncture, UV, and chemical resistance. They’re also less prone to stretching, making them suitable for tanks requiring a high degree of structural integrity.

Best suited for: Aggressive chemical storage, fuel or hydrocarbon containment, long-term use in extreme industrial conditions.

Polyurethane liners provide a tough, abrasion-resistant barrier that can withstand mechanical wear and harsh chemical environments. They adhere well to tank surfaces and offer flexibility without compromising strength. Polyurethane is often used as a spray-applied coating but can also be used in sheet form for liner fabrication.

Best suited for: Slurry tanks and abrasive fluids, mining process water with suspended solids, tanks requiring seamless, bonded coatings.

Whether you’re storing potable water or aggressive chemicals, the liner must be compatible with the contents. Potable water requires food-grade, certified materials like polyethylene (PE) or EPDM to meet health standards. While more corrosive or high-risk liquids, options like XR geomembranes or polyurethane are often necessary to prevent liner failure.

Tanks exposed to direct sunlight need UV-resistant liners like PE to prevent material degradation. Similarly, sites that experience temperature extremes require liners like EPDM that can maintain their integrity under thermal stress. For ground movement, vibration, and other physical impacts, flexible materials like XR Geomembranes are the ideal choice.

While some materials like PVC are lower in cost initially, they typically offer a shorter service life and may need replacing sooner. More durable options like EPDM and PE can last 20 years or more with minimal upkeep. Fo extreme conditions, reinforced liners such as XR Geomembranes or polyurethane coatings offer the best durability.

Liners must accommodate internal features like pipe penetrations, access hatches, and internal supports. Some liners are installed as one-piece, pre-fabricated drop-ins, which can speed up installation and reduce labour costs. Others, like spray-applied polyurethane, are installed on-site and require specialised equipment and trained applicators.

At Allied Pumps, we offer a full range of high-quality tank liners to go with our custom-built water storage tanks. Our liner options include PVC, polyethylene (PE), EPDM, and XR Geomembranes.

Whether you need a potable water solution or a liner that can withstand aggressive process fluids, we’ll help you choose the right material for the job. Unlike many suppliers, we handle both the supply and installation of our tanks and liners. This ensures seamless integration, quality control, and compliance from start to finish.

Contact us for more information about our tank liner options and galvanised steel tanks.

Contact us to learn about how we can help you with your pump needs.

CALL US NOW EMAIL US